Hornby J15 R3232

This is copied across from my other blog Albion Yard, I’m left wondering what to do with the Gibson kit now!

One of the latest items released by Hornby is the Great Eastern Wordsell designed Y14. The type first entered service in 1883 and was reclassified to arguable its more common designation of J15 after Grouping by the London & North Eastern Railway. The model as received depicts one of the class in their twilight years with the British Railways late crest, the subject locomotive being withdrawn in March 1963. The class was popular with both crew and enthusiasts. With a light axle loading the type was suitable for use on the light branch lines of East Anglia, for example it’s easy to locate images of the class working the Snape Maltings branch in Suffolk.

The model I’ve been poking and prodding is the OO 4mm scale late BR logo J15 R3232. It is supplied in the contemporary packaging of a vacuum formed protective cover which fits inside a cardboard tray with an outer sleeve. The locomotive was well protected and no components are loose or have suffered any damage in transit.

Included in the packing is a detail set including brake pull rods and the locomotive front coupling. Despite the models small size it weighs in at approximately 185g for the locomotive, the chassis block, footplate and boiler being metal castings. An additional weight is provided within the tender.

First impression often counts for me, and the J15 doesn’t disappoint. It immediately looks in proportion, edges are well defined and thin, particularly the cab roof and the color is a good opaque dull black with a very slight sheen to it. There are no paint blemishes and the detail printing is legible and clear. Like the K1 reviewed earlier on the blog, the yellow numbering looks to me a little too far towards a ‘lemon’ shade rather than a more cream color which I feel is correct. The wheel tyres and coupling rods are a pleasing steel color rather than bright chrome which blighted models in the not too recent past. Detail fittings are all correctly fitted and square and no evidence of excess glue around them. The prototype over its many years of service underwent a good number of detail changes. For the late livery as supplied it appears that Hornby have all the variations correct on this model and cross checking my available drawings the dimensions are correct too. The locomotive superstructure reflects the late chimney and dome in the forward position. Handrails reflect later era fittings with a continuous handrail above the smokebox face. Boiler mudholes are correctly offset on both sides of the engine and smokebox door is has the bevel edge and seating ring around the circumference. Smokebox dart is a separate fitting as are the lamp irons. The cab is represented with the later replacement steel plated roof and the cab sides the later smaller cut out. These are easily identified by the pronounced bowed effect of the cab profile and for the cab sides the tender rail and cab rails being of matching height.

Looking at the assembly of the superstructure components the join lines all indicate that If in the future Hornby want to backdate the model to an earlier Great Eastern or LNER version that will be possible. Cab detail is delicately modelled with separate fittings, the screw reverser aligning perfectly with the external rod to the mechanism. In front of the off side cab sits a Westinghouse brake pump which is well proportioned and crisply moulded.

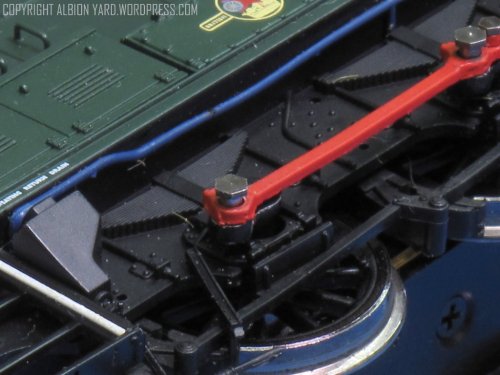

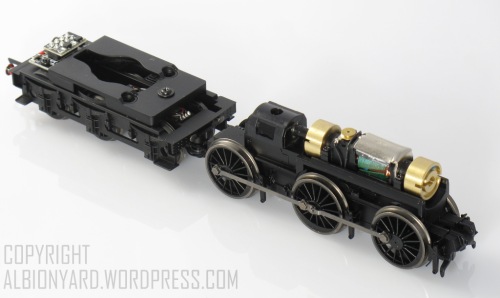

The chassis is an interesting piece of model engineering. In terms of detail, it matches the superstructure above. Below the firebox on the right hand side you can see the strengthening plate and Westinghouse pump drain. Brake shoes and pull rods are moulded in plastic and are correct shape and size. Wheels on this particular locomotive have balance weights as they should, for a ‘last forty’ batch engine, and non fluted coupling rods. Both locomotive and tender have the correct number of spokes ad profile wheels. The top of the chassis shows a representation of the inside valve gear and the underside of the boiler, allowing full daylight to be seen through the locomotive.

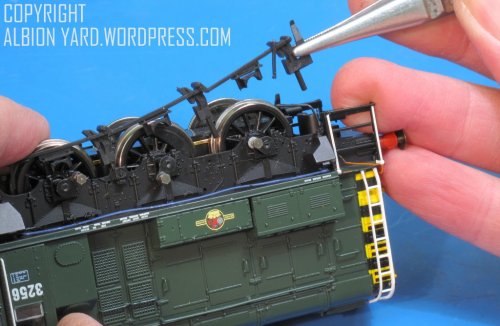

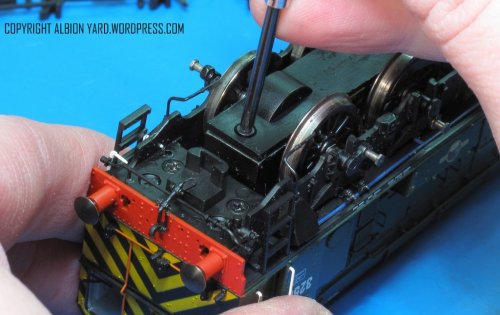

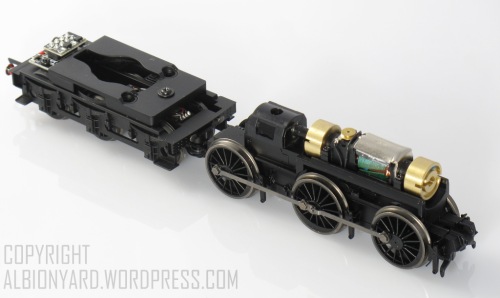

The chassis core is a metal casting with a plastic keeper plate that has phosphor bronze wiper pickups bearing on the rear of the tyre. All were in contact and the locomotive runs very smoothly through its full speed range without hesitation. The axles sit in circular brass bearings within the chassis block. The drive is to the rear axle, this is quite a challenge with a small open cab locomotive for it to remain hidden. The motor sits in a cradle which is the underneath of the boiler, and is fitted with two brass flywheels on extended shafts either end of the motor. Drive to the rear axle is taken via a plastic drive shaft to a gearbox tower that sits within the locomotive smokebox. The tower converts the drive via gearing to a plastic final drive gear to the rear axle, with all the mechanism enclosed within the chassis block, (more on this later). There is lateral movement of all axles though not excessive and clearance on the insides of the running plate splashers too. I’ve not measured it but my feeling is that the current chassis and running plate would likely accommodate an EM/S4 conversion with little (if any) modification.

All wiring is tidy and accurately soldered, another neat touch being the channel within the chassis for the wiring loom from locomotive to tender. The tender coupling has two positions to allow for normal operation and close coupling for display or gentler radius curves. I’ve had no issues on 36 inch radius curves with the close setting used.

The tender is correct for prototype and era. Like the locomotives they underwent changes throughout the life of the type. In terms of detail the tender shows the same degree of finesse and accuracy to era. Tender frame cutouts are correctly oval as opposed to ‘D’ shape on earlier engines, and the brakeshoes in line with the OO whelsets. The Fire Iron shield with the holder is in place as are external curved coal rails and the water gauge, all appropriate to the era portrayed. The brake cylinders for the Westinghouse pumps have been omitted; these are unlikely to have been visible and would probably have fouled the electrical connection between engine and tender. The molded coal insert for the tender is removable and shows the peculiar rectangular spaced coal bunker underneath, no gravity assistance for the poor fireman here!

The tender houses the 8 pin DCC chip blanking plate. The tender floor has slots which if fitting sound will help with the acoustics. Space is limited however and a sugar cube type speaker would seem a probable choice if fitting sound, and possibly the removal or reduction in size of the tender weight will help.

Whilst looking at the chassis of the J15 I wondered how it compared to a typical Bachmann product of a similar nature. In stock I had access to a Bachmann 3F and ‘C’ class. As the ‘C was more recent I thought it’d be interesting to see them side by side. As far as the prototype goes they were similar designs of similar sizes for similar work. Clearly this is not a true like for like, but interesting in looking at how the models differed.

Paint finish is excellent on both as are the lettering and logos. Hornby has a matt finish and the Bachmann, satin. In terms of detail the Hornby model has the edge in terms of finesse, in general lamp irons and small details are finer from Hornby.

The J15 tender chassis has brakes in line with the wheels where the ‘C’ class are integral with the outer frame. This doesn’t sound much but when seeing the two side by side there is a noticeable difference, but nothing a bit of old fashioned modelling can’t sort out for Bachmann’s ‘C’.

The loco chassis is the most interesting though. Bachmann choosing a centre axle drive and an enclosed motor, the model runs well and with this prototype Bachmann haven’t encroached into the space underneath the boiler. With the J15 and the smaller firebox Hornby could also have taken this ‘easy’ route, but have come up with an excellent design keeping the motor and mechanism hidden. The running properties are slightly smoother than Bachmanns, no doubt aided by the double flywheel. Both models have similar connections between engine and tender, but no close couple option from Bachmann. The tidy wiring from Hornby also being of note in this context too. The Hornby configuration has a good number of possibilities for small prototypes, length reduction can be achieved with one flywheel removed and a shorter cardan shaft to the gearbox.

For interest I placed a 14XX next to the J15 chassis. The current motor, gearbox and flywheel configuration would all work in a 14xx chassis with no cab encroachment. With quality cast superstructure like the J15 and a metal chassis with the metal boiler motor cradle, the possibilities for future development of detailed and well running smaller locomotive prototypes is intriguing indeed.

Overall then, a very competent and pleasing representation of the J15, to a high standard of finish and detail. Being the follow on release after the K1 the J15 keeps the same standards and possibly with the chassis and motor engineering, exceeds them. If these standards for toy train sets are kept this high we’ll be thoroughly spoilt. And frankly, why not?

Hornby R3232 J15 DCC Ready

Product ref LOT01-P91569

R3232-03-078